| Author |

Message |

very

Joined: Apr 16, 2008

Posts: 5

Location: New Delhi

|

Posted: Wed Apr 16, 2008 9:47 am Post subject:

bent pitch stick Posted: Wed Apr 16, 2008 9:47 am Post subject:

bent pitch stick

Subject description: has someone seen/fixed this before ? |

|

|

Hi everyone !

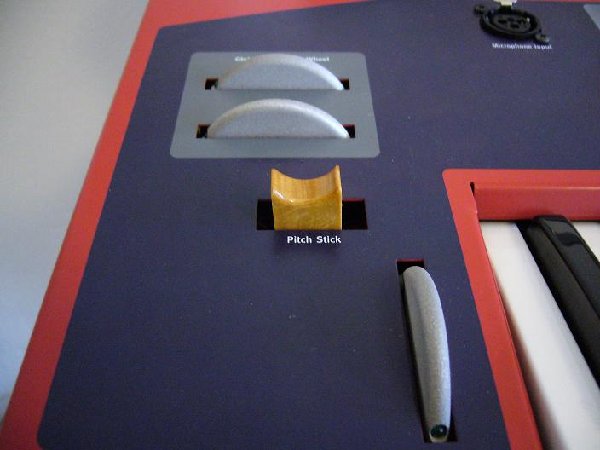

i bought a second hand g2x recently, everything is fine except for the pitch stick, which is not exactly centered. No big deal since it's perfectly functionnal, but i'd like to fix that at least for aesthetic purposes. (it will probably be more comfortable to play too) Has any of you ever dealt with something like that ?

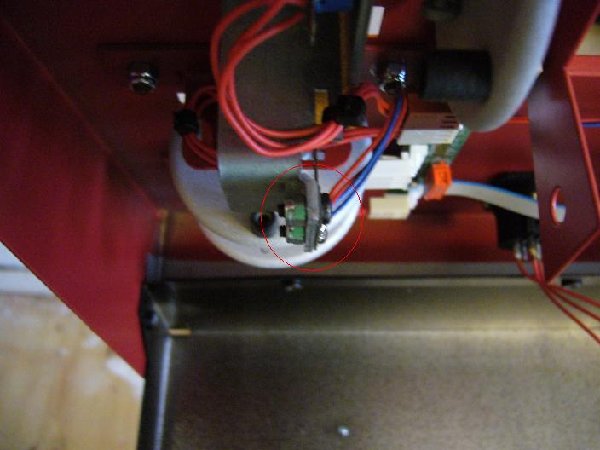

I've opened the case but couldn't figure out what i should do, the pitch stick (the wooden part) is attached to this quite thin metal blade and i certainly don't want to break this...

(and this is my first post so Hello everyone ! i've been reading you for quite a few weeks now, and i am learnig a lot of things, so thank you !)

here are two pictures... it's certainly not a huge problem, and i really might leave it like this, but still. the thin metal blade is straight, i guess it's the part on which it is fixed which is not bent enough !

| Description: |

|

| Filesize: |

46.34 KB |

| Viewed: |

232 Time(s) |

| This image has been reduced to fit the page. Click on it to enlarge. |

|

| Description: |

|

| Filesize: |

49.79 KB |

| Viewed: |

231 Time(s) |

| This image has been reduced to fit the page. Click on it to enlarge. |

|

|

|

|

Back to top

|

|

|

blue hell

Site Admin

Joined: Apr 03, 2004

Posts: 24461

Location: The Netherlands, Enschede

Audio files: 297

G2 patch files: 320

|

Posted: Wed Apr 16, 2008 2:21 pm Post subject: Posted: Wed Apr 16, 2008 2:21 pm Post subject:

|

|

|

very, and congratulations with the "X". very, and congratulations with the "X".

I'd not try to bend the metal pitch stick blade itself, it has some pressure sensitive resistors glued to it and people have been reporting problems with those loosening up without even trying to bend it.

_________________

Jan

also .. could someone please turn down the thermostat a bit.

|

|

|

Back to top

|

|

|

steve m

Joined: Apr 15, 2008

Posts: 19

Location: australia

G2 patch files: 1

|

Posted: Thu Apr 17, 2008 4:03 pm Post subject: Posted: Thu Apr 17, 2008 4:03 pm Post subject:

|

|

|

Hi, like you I have just purchased a pre-loved G2X. Can I ask how much you paid for yours ? I have been looking for one for ages and ended up bidding high on ebay to secure the deal and paid AU$2400, which is about EU1400, US$2250 or UK 1100. This is about the price of a new in-the-box G2 3 octave model from a music store, but I wanted the 5 octaves.

Was this over the top for a good condition 1 year old machine ? It's too late now, but I just wondered how it compares.

I will be opening it up this weekend to give it a good clean internally and to reset the Mains Voltage to 240v as it was supplied at 110v with a step down transformer which I do not want to use. I repair synths regularly so it should be an easy job. I will take a look at the pitch stick whilst I am in there and report back if I find anything useful for you.

_________________

Steve M - Australia

Nord Modular G2X, Korg Oasys 76, Kurz K2000, MiniMoog, Yamaha CS1x, Yamaha PSR8000, Korg Trinity Pro76. GEM Promega 3

Too many toys are never enough! |

|

|

Back to top

|

|

|

very

Joined: Apr 16, 2008

Posts: 5

Location: New Delhi

|

Posted: Mon Apr 21, 2008 11:55 am Post subject: Posted: Mon Apr 21, 2008 11:55 am Post subject:

|

|

|

hey,

thanks, i guess i'll leave it like it is for now, and maybe find a vendor who could do that for me...

Steve i've sent you a pm !

For the record i have paid 1400 euros for it. sounded like a fair deal, since i was able to test it and didn't have to pay postage. And like you i figured out that would be cheaper than a new g2, and i wanted more keys, and more dsp ! |

|

|

Back to top

|

|

|

Uncle Krunkus

Moderator

Joined: Jul 11, 2005

Posts: 4761

Location: Sydney, Australia

Audio files: 52

G2 patch files: 1

|

Posted: Mon Apr 21, 2008 5:11 pm Post subject: Posted: Mon Apr 21, 2008 5:11 pm Post subject:

|

|

|

Having done similar tweaking before, I'd recommend starting with the least invasive approach and see where you get before moving on to more radical (and possibly damaging) methods.

First, I'd look at that metal bracket and the way it attaches to the rest of the main structure. ie: - the end you can't see in the photograph. If it's screwed into place then I'd look at packing just a layer or two of 80gsm paper under one side of the attachment point. As it only needs to shift by a few degrees, this could sort it easily without making any permanent changes.

_________________

What makes a space ours, is what we put there, and what we do there. |

|

|

Back to top

|

|

|

very

Joined: Apr 16, 2008

Posts: 5

Location: New Delhi

|

Posted: Wed Apr 23, 2008 5:55 am Post subject: Posted: Wed Apr 23, 2008 5:55 am Post subject:

|

|

|

Uncle Krunkus, this sounds like a good idea !

i've just opened it again, so here it is : the blade with the receptor is screwed on a larger metal part, which is attached to the case with screws too. Unfortunately this metal part also holds the modulation wheel, so i can't put paper under it, since the modulation wheel is well positioned. (there are also a couple of wire coming from parts attached to this metal part, some of them seem to be soldered on the mainboard. The cables are not exactly loose so it would probably be tricky to remove this part)

I guess i could put some paper between the pitch stick blade and the piece it is attached to. I would try to do that but i need a thinner screwdriver to reach this ! maybe i'll try this later, if i get the proper tools. |

|

|

Back to top

|

|

|

|