| Author |

Message |

Rykhaard

Joined: Sep 02, 2007

Posts: 1290

Location: Canada

|

Posted: Sat Aug 09, 2008 10:36 am Post subject: Posted: Sat Aug 09, 2008 10:36 am Post subject:

Making your own knobs ...... Making your own knobs ......

Subject description: ...... a new idea?? |

|

|

Hey all. Some of you out there will know that I've been making my own knobs for my modular, for the last years - 1st from wine bottle cork and later from wood dowels - colouring in each of my knob's tops with pencil crayon art.

Whilst out touring in the Rockies the other day here in Alberta, I wondered at aluminum dowels. Not knowing how much they cost, if I could find one that is a proper diameter (0.75 to 1 inch), I could cut it to proper length and then possibly use coloured permanent markers to make my artwork on them that way.

This would also allow me to drill a hole in the side of each, then threading them, to screw in a threaded stopper to hold the knob onto the shaft.

THAT would solve my problem for properly attaching a wooden knob to an aluminum shaft.

Has anyone else ever done this before? I've no idea on the costs of aluminum in dowel format or, what type of blade that I would / could use to cut it to proper knob lengths. (1 to 1 1/4").

Thanks for any thoughts on this one.  My greatest desire is to solve my knob attaching to shaft problem. My greatest desire is to solve my knob attaching to shaft problem.  (Not wishing to keep using 2 part epoxy, which fixes them together permanently. (Not wishing to keep using 2 part epoxy, which fixes them together permanently.  ) ) |

|

|

Back to top

|

|

|

Clack

Joined: Aug 08, 2005

Posts: 438

Location: Walthamstow - london

Audio files: 5

G2 patch files: 1

|

Posted: Wed Aug 13, 2008 5:50 am Post subject: Posted: Wed Aug 13, 2008 5:50 am Post subject:

|

|

|

most knobs use a grub screw ( i love that name ) in the side were a hole is drilled and tapped (were the hole has a thread ).

In aluminium you can get a bolt to self tap the hole because its soft, or alternativly you can use a tapping tool and some grease to get a better hole

you could use a hacksaw to cut the rod and a file and some wet and dry to smooth the rough edges. The most difficult part would be drilling a hole in the side - you will almost definitly need some kind of vice to keep hold of it without drilling your hand.

I have been looking into casting my own knobs out of resins, as I work in a casting materials shop, problem is making and designing the original accuratly.

_________________

Clacktronics.co.uk |

|

|

Back to top

|

|

|

Uncle Krunkus

Moderator

Joined: Jul 11, 2005

Posts: 4761

Location: Sydney, Australia

Audio files: 52

G2 patch files: 1

|

Posted: Wed Aug 13, 2008 6:05 am Post subject: Posted: Wed Aug 13, 2008 6:05 am Post subject:

|

|

|

I recently converted some resin skulls into knobs. The hardest part for me was drilling the main hole square to the base, but I found I could do it by sticking them to a plate of aluminium and drilling through/perpendicular to that. I drilled and tapped little holes for the grub screw which was a 4mm one. It's interesting to note that the grub screw fixing is typical of so called "imperial" knobs, ie; they have a 1/4" main hole, and yet because they are now mostly made in Taiwan and other parts of Asia, they use a 4mm grub screw. The resin dealt really well with being tapped, and they turned out being very strong.

Have a look at my new bass pickup thread. I think you can see them there in the last couple of pics.

_________________

What makes a space ours, is what we put there, and what we do there. |

|

|

Back to top

|

|

|

Rykhaard

Joined: Sep 02, 2007

Posts: 1290

Location: Canada

|

Posted: Wed Aug 13, 2008 8:17 am Post subject: Posted: Wed Aug 13, 2008 8:17 am Post subject:

|

|

|

Alas, my home made aluminum knob idea has crashed.

When I checked pricing on aluminum rod's from the McMaster's catalog at work - a 6 foot length of 3/4 inch roung aluminum was $56! At 3/4 inch length per knob, that would be $0.60 per knob, before taxes. Add in all of the drilling / sanding / colouring in the top / polyurethaning (or something else) / etc. ...... no way jack.  Way too much cost. Way too much cost.

One of my coworkers suggested a certain type of Loctite product that may work well for a secure hold that COULD be broken (to free the wooden knob from the shaft), without damaging the pot. I'm going to do some tests with that Loctite product from work, as well as the standard white Lepage's glue.

At $4 per 4 foot length for wooden dowels, wood is still far FAR cheaper for making knobs. Hopefully - I'll be able to find a suitable glue that'll allow me to remove knobs in case I ever have to.  (Rare occurrence, thankfully.) (Rare occurrence, thankfully.) |

|

|

Back to top

|

|

|

richardc64

Joined: Jun 01, 2006

Posts: 679

Location: NYC

Audio files: 26

|

Posted: Wed Aug 13, 2008 9:07 am Post subject: Posted: Wed Aug 13, 2008 9:07 am Post subject:

|

|

|

| Rykhaard wrote: | One of my coworkers suggested a certain type of Loctite product ...

Hopefully - I'll be able to find a suitable glue that'll allow me to remove knobs in case I ever have to.  (Rare occurrence, thankfully.) (Rare occurrence, thankfully.) |

You might also try a product called "Hard As Nails." It's a fingernails hardener that supposedly prevents /reduces breakage. Find it in the Cosmetics section of the pharmacy. I've used it to seal screw heads.

_________________

Revenge is a dish best served with a fork... to the eye |

|

|

Back to top

|

|

|

Rykhaard

Joined: Sep 02, 2007

Posts: 1290

Location: Canada

|

Posted: Wed Aug 13, 2008 9:38 am Post subject: Posted: Wed Aug 13, 2008 9:38 am Post subject:

|

|

|

| richardc64 wrote: |

You might also try a product called "Hard As Nails." It's a fingernails hardener that supposedly prevents /reduces breakage. Find it in the Cosmetics section of the pharmacy. I've used it to seal screw heads. |

Now THAT's an idea!!  Thanks for that suggestion Richard! I'll give that a test, as well! Thanks for that suggestion Richard! I'll give that a test, as well!  |

|

|

Back to top

|

|

|

Peake

Joined: Jun 29, 2007

Posts: 1113

Location: Loss Angeles

Audio files: 3

|

Posted: Sat Sep 20, 2008 1:58 pm Post subject: Posted: Sat Sep 20, 2008 1:58 pm Post subject:

|

|

|

I'll say this with the straight face of someone who has absolutely no idea of what they are talking about: Hasn't anyone here looked into moulding? Pouring hot plastic into molds? Can't you make molds...I've seen something done once...

Ha! I don't know anything about it. If it were possible to DIY, you could always start with your favorite knob, say those EXPENSIVE COSMO knobs, and have a blast (furnace).

_________________

We are selling emotions, there are no emotions in a grid. -mwagener

"IC 741. Sometimes you don't want fidelity." -Small Bear Electronics Catalog |

|

|

Back to top

|

|

|

Uncle Krunkus

Moderator

Joined: Jul 11, 2005

Posts: 4761

Location: Sydney, Australia

Audio files: 52

G2 patch files: 1

|

Posted: Sat Sep 20, 2008 3:04 pm Post subject: Posted: Sat Sep 20, 2008 3:04 pm Post subject:

|

|

|

| Peake wrote: | Hasn't anyone here looked into moulding? Pouring hot plastic into molds? Can't you make molds...I've seen something done once...

Ha! I don't know anything about it. If it were possible to DIY, you could always start with your favorite knob, say those EXPENSIVE COSMO knobs, and have a blast (furnace). |

This is actually very do-able. Not with hot plastic, (although I s'pose that's possible) I've used polyester resin to make copies of things before. It's the same as potting resin. Very workable once it goes off too. You can cut, sand, drill, tap it quite easily. If you want an exact copy of another shape, you can make a mould out of FIMO, or latex rubber works well too. Don't add too much hardener to the epoxy though, as it will make it shrink slightly, and your final product will be up to say 5% smaller than the original. Too much hardener can also start a fire.

_________________

What makes a space ours, is what we put there, and what we do there. |

|

|

Back to top

|

|

|

Rykhaard

Joined: Sep 02, 2007

Posts: 1290

Location: Canada

|

Posted: Sat Sep 20, 2008 10:35 pm Post subject: Posted: Sat Sep 20, 2008 10:35 pm Post subject:

|

|

|

One of the key things that I have to be able to do on the faces of the knobs for my machine though, is draw the symbols / pictures related to the knob's actual function.

Though I still haven't yet tried the suggestions for adhering the knobs to the shafts, I'm going to stick with the wooden dowels as they're the cheapest and easiest to make knobs from.

The Hard as Nails suggestion, I like lots and lots.  |

|

|

Back to top

|

|

|

diablojoy

Joined: Sep 07, 2008

Posts: 809

Location: melbourne australia

Audio files: 11

|

Posted: Wed Oct 01, 2008 3:08 am Post subject: Posted: Wed Oct 01, 2008 3:08 am Post subject:

|

|

|

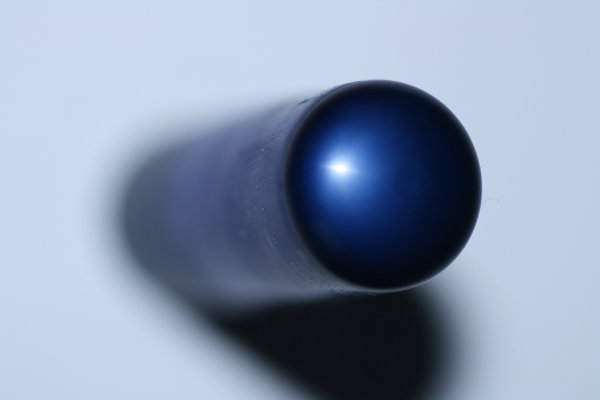

some knobs i made a while back from aluminium

1/2 inch stock turned on an ordinary pedastal drill

stock is held in the chuck and an old 1/8 drill bit ground to

to make a cutter which is held in a cross slide vise it is a very slow process as you can't apply too much pressure so you can only take very small amounts off at a time but doable with some patience the grips are simply 7mm i/d silicon vacuum tube from an auto parts supplier.

| Description: |

|

| Filesize: |

506.62 KB |

| Viewed: |

314 Time(s) |

| This image has been reduced to fit the page. Click on it to enlarge. |

|

| Description: |

|

| Filesize: |

1.67 MB |

| Viewed: |

297 Time(s) |

| This image has been reduced to fit the page. Click on it to enlarge. |

|

| Description: |

| the larger one in the middle is from 25 mm stock with 13 mm tubing for the grip |

|

| Filesize: |

692.9 KB |

| Viewed: |

286 Time(s) |

| This image has been reduced to fit the page. Click on it to enlarge. |

|

|

|

|

Back to top

|

|

|

revtor

Joined: Oct 05, 2005

Posts: 79

Location: NewJersey, USA

|

Posted: Tue Oct 28, 2008 3:57 pm Post subject: Posted: Tue Oct 28, 2008 3:57 pm Post subject:

|

|

|

You would use a lathe to turn the aluminum to the shape and also drill the hole for the pot shaft. Drilling and tapping the hole for the grub screws would be tricky, but is doable... drillpress, centerpunch and drillbits/taps. use oil.

making many knobs like this? unless you need another hobby, id say no way.

casting knobs is the way to go. (smooth-on.com) carve one from whatever you want. wax plaster, wood, etc.. then cure silicone around it in a block, and after it cures, slice it off neatly to give you two halves. Take out the original, and put the two sides back together, there's your mold. fill it with liquid plastic, its cured in an hour, or 5 minutes depending on the plastic you choose.. and youll be popping these out., use your first copy to make another mold and then you can cast two at a time...

alternately, get someone to draw in CAD your desired knob and send it to a jobshop somwehre with CNC lathes. se what they'll charge you. do a cool design and try to recruit as many of us DIY'ers as you can to get the quantity up, so the price goes down.

have fun. tweak yer knobs.

~Steve

_________________

beep blurp flurrrp fiszzzzp pow bakka wakka wakka -A synth freaks mental notes. |

|

|

Back to top

|

|

|

bubblechamber

Joined: Nov 04, 2006

Posts: 280

Location: NYC

Audio files: 1

|

Posted: Tue Oct 28, 2008 5:02 pm Post subject: Posted: Tue Oct 28, 2008 5:02 pm Post subject:

|

|

|

and of course there not reason to simply stop at aluminum fab for knobs... then we'll need to move on to DIY anodizing...now i just need a hazmat suit....

http://www.focuser.com/atm/anodize/anodize.html

_________________

You can check your anatomy all you want, and even though there may be normal variation, when it comes right down to it, this far inside the head it all looks the same. |

|

|

Back to top

|

|

|

Tasmanian Alkaloid

Joined: Jun 29, 2008

Posts: 116

Location: Isle De Mort

|

Posted: Wed Nov 12, 2008 11:27 am Post subject: Posted: Wed Nov 12, 2008 11:27 am Post subject:

|

|

|

| diablojoy wrote: | some knobs i made a while back from aluminium

1/2 inch stock turned on an ordinary pedastal drill

stock is held in the chuck and an old 1/8 drill bit ground to

to make a cutter which is held in a cross slide vise it is a very slow process as you can't apply too much pressure so you can only take very small amounts off at a time but doable with some patience the grips are simply 7mm i/d silicon vacuum tube from an auto parts supplier. |

These look fantastic!!!! |

|

|

Back to top

|

|

|

Rykhaard

Joined: Sep 02, 2007

Posts: 1290

Location: Canada

|

Posted: Wed Nov 12, 2008 12:12 pm Post subject: Posted: Wed Nov 12, 2008 12:12 pm Post subject:

|

|

|

Those ARE extremely cool looking!

My final solution that I came to a few weeks ago for sticking my wooden knobs to the pot's shafts, is to drill a small hole into the side of the knob, to allow a WOOD screw (with deep threads) to grab the wood and pressure fit it against the shaft.

And?

It works beautifully.  On rotary switches as well as pots. Strong force, will not loosen the knob from the shaft. On rotary switches as well as pots. Strong force, will not loosen the knob from the shaft.

I DO have to be careful though as to not tighten it TOO much or the knob will crack.

Finally though, a solution that works.  There'll be photos at some point, once I start getting a good amount of the finished knobs attached to the shafts. There'll be photos at some point, once I start getting a good amount of the finished knobs attached to the shafts.  |

|

|

Back to top

|

|

|

blue hell

Site Admin

Joined: Apr 03, 2004

Posts: 24535

Location: The Netherlands, Enschede

Audio files: 299

G2 patch files: 320

|

Posted: Wed Nov 12, 2008 1:46 pm Post subject: Posted: Wed Nov 12, 2008 1:46 pm Post subject:

|

|

|

| Rykhaard wrote: | | I DO have to be careful though as to not tighten it TOO much or the knob will crack. |

When you could find some suitable metal pipe you could make anti-crack rings from that maybe.

_________________

Jan

also .. could someone please turn down the thermostat a bit.

|

|

|

Back to top

|

|

|

umschmitt

Joined: Jun 29, 2011

Posts: 189

Location: brrlin

Audio files: 11

|

Posted: Tue Sep 20, 2011 6:01 pm Post subject: Posted: Tue Sep 20, 2011 6:01 pm Post subject:

|

|

|

So the question has already been discussed (in the developers corner, that's nice)…

I've been wondering for ages how I could make diy knobs, using if possible common and affordable objects. I thought I'd share my poor man's experience. I once made 'slices' from a broomstick, nice wooden aspect, but the problem was to drill a hole in the exact middle of them… I also tried wooden pearls, which already have holes, but then I had to fill the hole at the end. Now I didn't try yet a solution with acorn nuts (+ rubber around the pot shaft), which would bring a neat industrial look. I must admit I have no idea how much these nuts could cost though.

Having written that, I got to ask : does anyone have some more brilliant ideas to share ? Don't be ashamed ! The cheaper, the better !

_________________

::U::N::S::C::H::N::E::L::L:: |

|

|

Back to top

|

|

|

Uncle Krunkus

Moderator

Joined: Jul 11, 2005

Posts: 4761

Location: Sydney, Australia

Audio files: 52

G2 patch files: 1

|

Posted: Tue Sep 20, 2011 6:21 pm Post subject: Posted: Tue Sep 20, 2011 6:21 pm Post subject:

|

|

|

Fimo is the first to come to mind.

You could even push it into a mould made from another type of knob.

It may be expensive though.

DAS or some other kind of refined paper mache product would be cheaper. You could possibly make that kind of stuff yourself with recycled newspapers, PVA, Polyfilla and a Bamix!

Whatever it is, it needs to be hard enough to sand, drill, possibly even tap.

How about something which would look just as good un-centred? Like bone?

Cast resin? (messy, exacting, brittle and possibly more expensive than commercial knobs)

_________________

What makes a space ours, is what we put there, and what we do there. |

|

|

Back to top

|

|

|

umschmitt

Joined: Jun 29, 2011

Posts: 189

Location: brrlin

Audio files: 11

|

Posted: Tue Sep 20, 2011 7:03 pm Post subject: Posted: Tue Sep 20, 2011 7:03 pm Post subject:

|

|

|

Fimo, of course…

| Uncle Krunkus wrote: | | DAS ... PVA, Polyfilla and a Bamix |

Errr… what are these ? Brands ? Please explicit ! [edit : nevermind, search engines are made for this]

| Quote: | | How about something which would look just as good un-centred? Like bone? |

Like in dead animals, you mean ? (oh yeah : TEETH !)

Another direction : any collection of tiny, drillable objects, like dices. Yes the result could be somewhat special.

_________________

::U::N::S::C::H::N::E::L::L:: |

|

|

Back to top

|

|

|

diablojoy

Joined: Sep 07, 2008

Posts: 809

Location: melbourne australia

Audio files: 11

|

Posted: Tue Sep 20, 2011 9:00 pm Post subject: Posted: Tue Sep 20, 2011 9:00 pm Post subject:

|

|

|

tried casting resin once

fast but only worked about 50% of the time

does not like thread tapping for grub screw which is where it failed

for me. if the threads could be cast in might be better but they would still be fairly fragile. I might try again one day as the ones that worked are still going ok

resin would be better suited for splined shafts you just need to find twenty or so stuffed spline shafted pots to destroy:lol:

can be coloured easily, transparent red, green or blue anyone ?

_________________

In an infinite universe one might very well

ask where the hell am I

oh yeah thats right the land of OZ

as good an answer as any |

|

|

Back to top

|

|

|

umschmitt

Joined: Jun 29, 2011

Posts: 189

Location: brrlin

Audio files: 11

|

|

|

Back to top

|

|

|

diablojoy

Joined: Sep 07, 2008

Posts: 809

Location: melbourne australia

Audio files: 11

|

Posted: Wed Sep 21, 2011 2:49 pm Post subject: Posted: Wed Sep 21, 2011 2:49 pm Post subject:

|

|

|

well its not too hard to do really

just need to do some research for a supplier

casting resin is usually stocked at most hardware stores

though better if you can find some one who specialises try google for someone nearby.

2 basic steps make a mould from something say a one inch deep

aluminium or plastic tray and some fast setting silicon moulding rubber again google for a supplier for this

prepare a top plate with holes for 20 or so pots to suspend at the right height above the tray with some guides to keep it positioned correctly

mount your favourite shape knobs you wish to copy on the pots and plate and fill the tray with the silicone once that has cured remove and take off

the knobs leaving the shafts of the pots still attached to the plate

fill your now completed mould with the casting resin and reinstall the plate

if your plate guides are at all accurate the pot shafts will be centered and at the correct depth scape of any excess with a straight edge let that cure and you will have twenty knobs ready to go

if your planning to use splined shafts it should in theory work out fine

note i have not done it this way myself yet but it's how i would try next time.

for colouring the resin look in the paint section at the hardware store for

color tints for varnish or wood stain there's usually a nice red, yellow, green, blue and black to be had and you can mix and match a bit or swirl it a bit even before it starts to set.

don't buy massive amounts of the casting resin , once the cans opened it has a limited life span.

cheers and good luck if you try it.

any further questions just post it and i will try to help here.

_________________

In an infinite universe one might very well

ask where the hell am I

oh yeah thats right the land of OZ

as good an answer as any |

|

|

Back to top

|

|

|

diablojoy

Joined: Sep 07, 2008

Posts: 809

Location: melbourne australia

Audio files: 11

|

Posted: Wed Sep 21, 2011 2:53 pm Post subject: Posted: Wed Sep 21, 2011 2:53 pm Post subject:

|

|

|

one other idea i toyed with for a while

if you built a REPRAP machine you could just print out your knobs

_________________

In an infinite universe one might very well

ask where the hell am I

oh yeah thats right the land of OZ

as good an answer as any |

|

|

Back to top

|

|

|

inlifeindeath

Joined: Apr 02, 2010

Posts: 316

Location: Albuquerque, NM

|

Posted: Thu Sep 22, 2011 11:19 am Post subject: Posted: Thu Sep 22, 2011 11:19 am Post subject:

|

|

|

i love this idea and was going to try it out a while ago with some wine corks. Ryk, how'd the corks work out? I'm going to give it a shot here soon, but does anyone know where I can get some of those 'grub screws' for a good price?

_________________

http://www.youtube.com/user/borisandfef |

|

|

Back to top

|

|

|

umschmitt

Joined: Jun 29, 2011

Posts: 189

Location: brrlin

Audio files: 11

|

|

|

Back to top

|

|

|

diablojoy

Joined: Sep 07, 2008

Posts: 809

Location: melbourne australia

Audio files: 11

|

Posted: Thu Sep 22, 2011 2:16 pm Post subject: Posted: Thu Sep 22, 2011 2:16 pm Post subject:

|

|

|

| Quote: | | Why built it ? Couldn't I just print it ? |

haha yeah you can print a lot of it

if you know someone who already has a REPRAP up and running that is

though there is a reasonable community growing up around it now

everything can be bought and assembled

could be cool for printing out panels also

_________________

In an infinite universe one might very well

ask where the hell am I

oh yeah thats right the land of OZ

as good an answer as any |

|

|

Back to top

|

|

|

|